Week 8-9

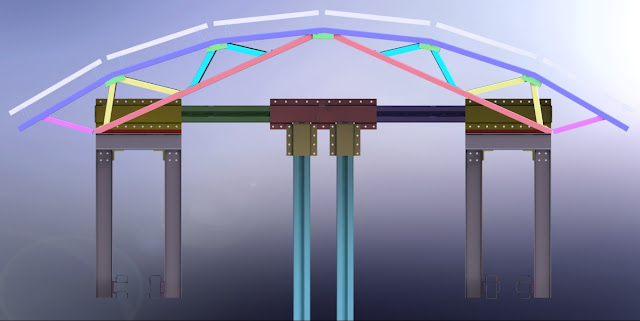

Figure 1. Final support

During the last two to three weeks, I have been researching and designing supports in order to support the solar panels on top of the main structure. I came up with two designs; most components of both designs are made out of sheet metal. However, based on my knowledge, manufacturing the first model (figure 2 and 3) might be hard because of the length of the pieces and the type of bends that they require. Due to the difficulty of manufacturing this support, I decided not to complete my design and did not put any bolt holes on the support.

Figure 2. Solar panel support 1 (isometric view)

Figure 3. Solar panel support 1 (front view)

For the solar panel supporting rail, I used a GS-MR-L Grasol rail (figure 3). This rail is made by extruding aluminum. Grasol also manufactures mounts in order to mount solar panels on the rails. They use a specific type of extruded aluminum support beam to support the rails. This allows the assemblers to adjust the panels and the rails easily. However, for the purpose of our model this is not necessary. The rails can be assembled on the support, using clamps.

Figure 4. Supporting solar panel Grasol rail

Based on the suggestion of our architect, initially I was planning on using curved solar panels for the design, but after attending the Intersolar exhibit, I realized that not many companies manufacture curved solar panels. The companies that manufacture curved solar panels, mostly manufacture them for backpacking purposes, or are made out of thin film, which have a very low efficiency. Based on my research, I decided to use flat monocrystalline solar panels and designed the support in a way to get a curve final look after assembling the solar panels. It would be ideal for our project to use solar panels which are less than two meters in length and 1 meter in width. After doing some research, I decided to use an LG 365N2W-B3 72 cell solar panel, which has a length of 1.96 meters and a width of 1 meter. I designed this solar panel on SolidWorks using the same dimensions. This model can be seen in figure 5.

Figure 5. LG 365N2W-B3 72 cell monocrystalline solar panel

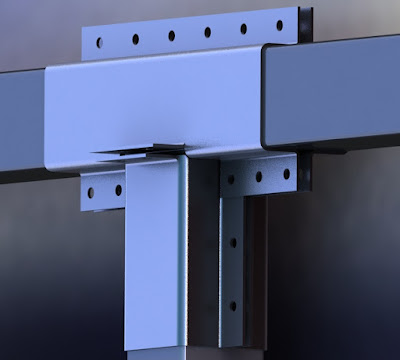

I used a different approach in order to design the second solar panel support. I used four main panels, which are connected to each other using U brackets in order to support the solar panels. All these pieces can be made by laser cutting or plasma cutting and bending sheet metal. The second design of the solar panel support can be seen in figure 1, 6.

Figure 6. Solar panel support 2 (isometric view)

Comments

Post a Comment