Week 8-9

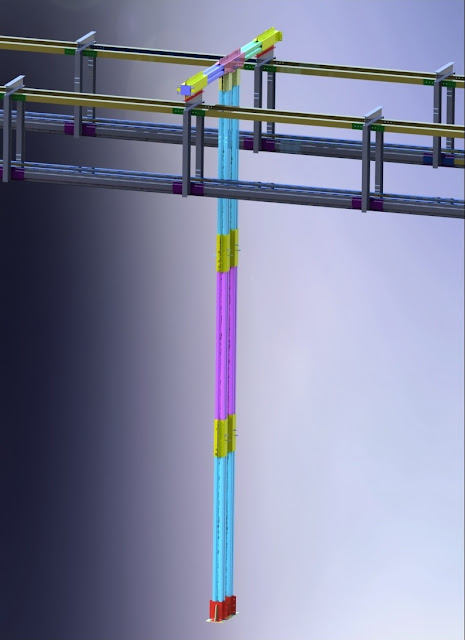

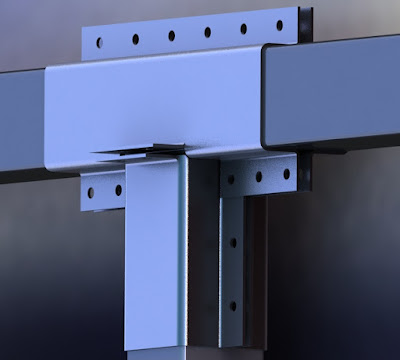

Figure 1. Final support During the last two to three weeks, I have been researching and designing supports in order to support the solar panels on top of the main structure. I came up with two designs; most components of both designs are made out of sheet metal. However, based on my knowledge, manufacturing the first model (figure 2 and 3) might be hard because of the length of the pieces and the type of bends that they require. Due to the difficulty of manufacturing this support, I decided not to complete my design and did not put any bolt holes on the support. Figure 2. Solar panel support 1 (isometric view) Figure 3. Solar panel support 1 (front view) For the solar panel supporting rail, I used a GS-MR-L Grasol rail (figure 3). This rail is made by extruding aluminum. Grasol also manufactures mounts in order to mount solar panels on the rails. They use a specific type of extruded aluminum support beam to support the rails. This allows the assembler...