Week 2

Week 2

I started this week by

working on new designs to solve the problems that we are having with the

switch. At the switch, the wheels of the bogie hit the front part of the rail,

which causes vibration, is noisy, and puts a lot of stress on the bogie and the

track. Besides the designs that I posted last week, I came up with a new design

(figure 1) that uses cables to support the pod car at the switch. In this system

the cable matches the speed of the bogie, and the bogie connects to the cable.

After the connection has been made, the majority of the weight of the pod car

and the bogie will be supported by the cable; this prevents the wheels of the

bogie from colliding with the front part of the track even if the mechanism

that allows the pod car to move on a single track would fail.

Figure 1. Cables supporting the pod car.

I also worked on a new

mechanism for switching (figure 2). The current switching mechanism, switches

the tracks by applied a force on the side of the track using a set of wheels.

This disables us from placing ribs or brackets flat on the side of the track.

The mechanism that I have proposed uses another set of rails underneath the

previous ones. These rails will be hollow inside, with a grove on one side.

Before switching, a mechanism pushes a set of wheels inside the rail on one

side of the track. After the wheels are fully extended, they rotate 90 degrees

and come in contact with the inner side of the rail. The wheels then prevent

the pod car from moving in the opposite direction.

Figure 2. Switch.

After the switch, I

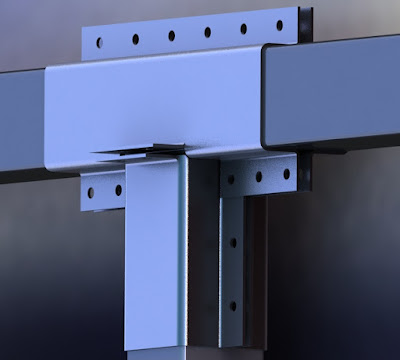

started working on the main supports (figure 3). To simplify the model, I used

rectangular beams instead of cross beams. Since, the cross beams cannot be

bent, I used clamps to connect the beams to each other in order to create a

curve to support the load of the horizontal beam.

Figure 3. Main support.

Initially, I was

planning on bolting down the center and the side clamps (figure 4) to the vertical

and horizontal beams. In order to avoid using bolts, which would reduce the

strength of the material, it is possible to use cables to connect the right

clamp and the bottom clamp in figure 4 to the clamp on the top left of the

figure. The tension created by the cable and the beams in between the clamps

would prevent the clamps from moving.

Figure 4. Clamps.

After designing the main

support, I assembled all the parts to show what the semi-complete system looks

like. The assembled parts can be seen in figure 5.

Figure 5. Semi-complete system.

As I mentioned in my

previous post, the new system that I am proposing uses another set of bogies,

which comes in contact with the upper tracks and lift the bottom bogies from

the track; this prevents the wheels of the bottom bogie from colliding with the

front part of the rail. The upper tracks start right before the switch and end

right after it. I made the upper tracks with a slope (figure 6), so that the

wheels of the top bogie would slowly come in contact with the upper tracks and

lift the bottom bogies of the rails. This transition can be made as smooth as

possible by adding springs and dampers to the system.

Figure 6. Curved upper tracks.

After finishing my

designs, I met Claude, the inventor of cross beams. Based on the information

that I received from him, we are not going to use the support that I have designed.

For the new design, the cross beams will be connected to each other using

friction joints, and the tracks will be five meters away from each other. Since

this distance is very small, the arched support that I added to my design can

be removed, and if a support is needed, a single cross beam can be used to

support the weight of the horizontal beam.

Currently I am mapping

the layout of the tracks that we are going to build in the near future. We have

a small area to work with and there are many obstacles on our way. The layout has

to meet certain criteria in order to get approved by the city hall.

Comments

Post a Comment